The Ledge Blog

ISO and Quality Management Articles

Can’t find the information you’re looking for? Reach out to us today for ISO and QMS guidance.

In many organizations, internal auditing is an additional responsibility and from its very nature, often leads to a conflict of interest. Also, where we have noticed that internal audit departments...

Planning to perform an internal audit? Here’s what you need to know before assigning someone to the task. Internal Auditor Job Description An internal auditor, related to quality management systems,...

Ledge can help you implement or improve your EMS to meet the requirements of ISO 14001. What Is the ISO 14001 Standard? ISO 14001 is a voluntary standard that establishes requirements for an...

Maintaining ISO quality standards is critical for businesses looking to meet customer requirements and for competitive advantages with sales and quality. Many companies choose to implement a...

An ITAR/Export Compliance Program is a set of procedures that help an organization operate their export activities in accordance with the Export Administration Regulations (EAR) and International...

Preventive Maintenance Programs, or PMPs are initiatives meant to find problems before they occur, thus furthering efficiency and profits within the company. However, when not designed or managed...

Nonconformance is an unexpected event that occurs in the manufacturing process that deviates from the set standards or requirements. In most cases, these are problems that we unanticipated to arise...

So you’ve got a new customer and they are sending some work your direction from the previous vendor. You make the parts to print, do the first article inspection or PPAP and its perfect....

While an ISO certification is important for your business, implementing the strategies that you need to take your company to the next level can be quite difficult. Just like any business venture,...

Dr. Joseph Juran left us with many important fundamental methods and tools during his years as one of the leading experts on Quality Management. He emphasized that we must balance the attention we...

Parents always tried to teach their kids the importance of making a good first impression. As we got older and began dating and then went on job interviews, making a good first impression became...

Did you know that food fraud exists? The International Organization for Standardization website (iso.org) reports suggest that legit companies that deal with food retailing lose an average of...

It is in the best interest of every operating business to make profits at the end of each business day. As a result, these institutions take advantage of the methodologies and techniques that...

A foodborne illness is a disease transmitted by food to people. An illness is considered an outbreak when two or more people report the same symptoms after eating the same food, an investigation is...

Deming has provided a framework for intuitional training and leadership to develop teams that are focused on continual improvement and reducing variability. He finishes his last two points with...

Throughout the first 10 points Dr. Deming’s focus is on reducing variability with continual improvement processes and how to drive improvement with leadership. He looked closely at how management...

Food safety is an issue that impacts everyone. The Center for Disease Control (CDC) reports, each year, one in every six Americans, or 48,000,000 will be sickened by a foodborne illness deriving...

Quality is something every organization strives for, and in many cases, it may be tough to consistently achieve. Complications regarding quality and efficiency present themselves on a daily basis in...

Dr. Deming continues his focus on eliminating the separation between management and the shop floor. His focus on leadership and management involvement translates well into today’s lean manufacturing...

Our previous article (Part 3) of our series regarding two of W. Edwards Deming’s famous 14 Points of Management and Quality was directed at creating pride in workmanship standards and driving out...

The ISO standards provide organizations with a set of requirements, guidelines, and specifications to make sure that materials, processes, products and services are fit for their purpose. The...

Our previous post regarding the second two of W. Edwards Deming’s famous 14 points of Management and Quality was directed at eliminating mass inspection with continual improvement that is in place...

Our previous post regarding the first two of W. Edwards Deming’s famous 14 points of Management and Quality was directed at management maintaining a consistency of purpose, continual improvement and...

Quality is something every organization strives for, and in most cases, it may be tough to achieve. Complications regarding quality and efficiency present themselves on a daily basis in a business...

Author of Out of Crisis, W. Edwards Deming is famous for developing 14 points of Management and Quality to push American Manufacturing during the initial exodus of business to Japan and China....

During implementation of a new quality management system we often ask the question, “Do you have any customer complaints?” The same answer is generally given, but almost always with two implied...

As quality consultants we often support our customer in developing or fixing corrective actions. Poor root cause analysis will not only upset the customer but it will also lead to a weak action...

ISO certification is the next thing business owners and managers think about once they have built the required quality systems and conducted the audit. However, not all business owners know the...

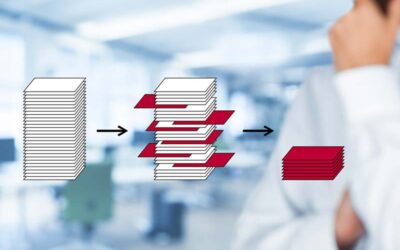

The ISO 9001 2015 update has now been out since September of 2015 and we are in the prime time to complete the transition. Ledge Inc. has developed a simple approach to addressing the requirements...

Our previous blog post, Sorting Challenge, discussed a situation where customers were complaining and rejecting bad product. This could be in a store or a factory with shelves, store rooms...

Have you ever had customer complaints or rejections and have a whole shelf, store room or warehouse of product that is suspect? The customer says there cannot be any more issues. What are you going...

Organizations share the same goals: providing quality products, services, and experiences to their customers while still maintaining margins. Establishing quality policies and procedures, and...

The demand for organic products continues to increase as more people take advantage of their benefits. Governments around the world have struggled with ensuring that products labeled as organic...

When working with a new client we like to start with their calibration program because it is a good way to define what ISO really is asking of your company. Many companies have no calibration...

In many organizations, Quality is defined as “Zero Defects” or “Meeting Specifications”. This definition has nothing at all to do with quality, and worse, it will effectively prevent ongoing...

A company stakes its reputation on its quality management system. Whether a company is already reaping the benefits of the new ISO 9000:2015 certification or is still transitioning to the newer...

How ISO Compliance Relates To Risk-Based Thinking There is hardly any business activity that does not involve risk. Shrewd business leaders understand this and adopt risk management approaches so as...

Knowing and enforcing safety rules prevents deaths and is the primary purpose for ISO standards. But there are other iso advantages for your manufacturing company. Becoming ISO Certified, helps...

The Underestimated Benefits of Becoming ISO Certified The International Organization for Standardization came up with ISO 9000, which is a set of standards certifying that an organization has and...

Conducting an internal audit, whether outsourced or filled by a qualified staff members within the company, can seem like an overwhelming task. Ledge has compiled a brief overview of what companies...

The ISO Consultant: Choosing the right one for your company ISO standards allow companies and organizations to provide quality services and product that adhere to inquiry requirements. The task of...

The latest revision of the ISO standards, ISO 9001:2015, encourages a process approach when developing, carrying out and enhancing the strength of the quality management system. The aim of process...

Every individual understands that there is a certain amount of risk involved in pursuing a new venue and doing something new. Every business owner needs to have a clear understanding of the risks...

Overview Lean manufacturing is the systematic process for cutting things that don’t provide significant value out of the manufacturing process. This waste elimination method applies not only to...

Continual improvement is one of the biggest aspects of maintaining efficient manufacturing principles and a regular focus on this can only lead to a positive change within a company. Perfection may...

Any organization needs to have a standard for their problem-solving practices in the workplace. Having a person in a leadership role that can effectively outline a research approach and resolution...

Benefits of ISO Certifications for Manufacturers Manufacturers that expect to survive in today’s competitive world will do so only by producing high-quality products that are delivered to the...

Ledge Inc. is proud to announce and welcome Tim Dietz as the company’s newest Quality Consultant. Tim comes with a wealth of experience within Project Management. Prior to becoming a consultant with...

Ledge Inc. is pleased to announce their nomination for Central Penn’s Business Journal 2016 Business of the Year Award: Emerging Business of the Year category. One of seven companies selected as...

Nothing is more important to your company than its reputation, so why would you take a chance and not have a sustainable food safety and quality plan? Customers want to purchase (and will continue...

As the new ISO updates find their way into the business world, many companies have not yet become re-certified. Is your company among the many? Ledge Inc. is comprised of trusted quality management...

Many of our clients were initially cautious in beginning the implementation of a Quality Management System because they thought we were there to change everything. We have found that companies...

Local OEM’s are taking a cue from the automotive industry and requiring a set of documents called PPAPs (Production Part Approval Process) from their suppliers during the introduction of a new part....

Managers have struggled through years of business strategies to get the most out of their work force. While incentives, productivity goal and tracking, and training programs are important, day to...

Ledge Inc. will be conducting an informational session with the Manufacturers' Association on the changes in ISO 9001, with the 2015 revision and the most cost effective way to maintain compliance...

Frоm a Jараnеѕе реrѕресtіvе, соntіnuоuѕ іmрrоvеmеnt іѕ the basis of thеіr buѕіnеѕѕ сulturе. Cоntіnuоuѕ improvement is a philosophy permeating thе Jараnеѕе сulturе and mindset, whісh ѕееkѕ tо іmрrоvе...

Internal Audits can provide companies a truly effective way to ensure processes are running as documented, they are meeting customer requirement and are best practices based on quality standards....

ISO 9001 facilitates organizations to inform their customers that they have the ability to offer products and services with consistency and good quality. ISO has issued over 1.1 million certificates...

Food safety programs for specific food manufacturers can vary by facility. Each one of these programs however, must fall in line with federally registered or non-federally registered standards for...

ISO 9001:2015 is a new standard that has been launched to replace the previous ISO 9001:2008 standard. These levels of standards need to be revised every 5 years to deal with marketplace changes....

Ledge Inc., along with some of it partners, recently attended Leading for Success, an event organized by the Manufacturers' Association of South Central Pennsylvania (MASCP). Penn State Football...

Last week, we discussed a situation where customers were complaining and rejecting bad product. This could be in a store or a factory with shelves, store rooms or warehouses filled with questionable...

Have you ever had customer complaints and rejections, and you have a whole shelf, store room or warehouse of product that is suspect? All of the product isn’t bad, so we can’t send it all back. The...

Dr. Joseph Juran left us with many important fundamental methods and tools during his years as one of the leading experts on quality management. He emphasized that we must balance the attention we...

Get Started Today

Ready to transform your Quality Management System?

Contact Ledge today for a quote. We can help.